Model :

26" / 30" / 32" ENC Series

- The rigid construction bed are induction hardened over HRC50 and precision ground provides heavy duty turning and fine finishing at high accuracy.

- The main spindle is supported by selected and preloaded super precision bearings to ensure high accuracy through full speed ranges.

- The main spindle, shafts and gears in the headstock are made by high grade alloy steel, are hardened and precision ground for high speed running at lower noise level.

- The automatic lubrication pump equipped on apron provides all slide-ways and two axes ballscrews lubricants continually.

- The hardened and precision ground ballscrews for X & Z axes are mounted on high precision bearings to enable sensitive movement.

- Both X & Z axes equipped with individual electronical handwheels on control panel for manual operation as conventional lathes.

- Widely & semi-enclosed front chuck & chip guard equipped with interlock switches according to EC regulation provides safety and easy operation.

- Full length rear splash guard and front moveable chip trolley provides chip and coolants safety and easy clean ..A designed openable door on rear splash guard provide for X-Axis and home switches maintanence and adjustment easily.

- Both X & Z axes are equipped with selected controller whole package AC servo motors with its own power supply and monodrives.

- The EUCHNER automation sensor equipped on spindle speed changer to provide the exactly positions of speed range for spindle infinitely variable speed selection correctly.

- Electric positional stops in X & Z axes and tailstock to avoid any over travels. The modular input/output card evidence all control system performance for maintanence and trouble shooting easily

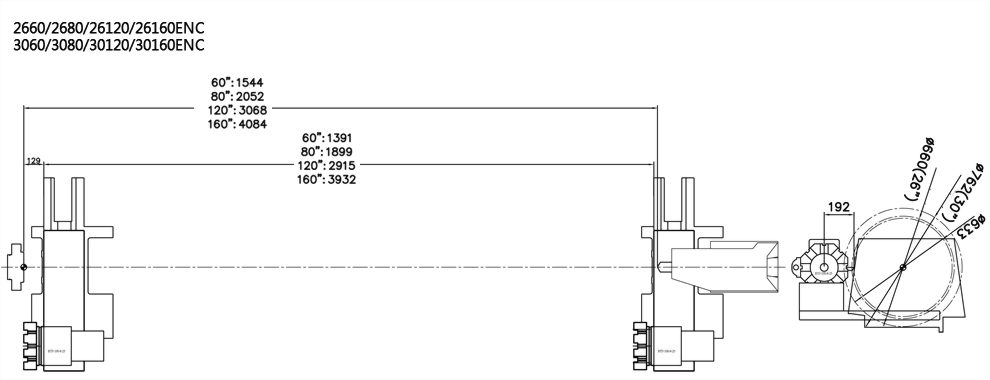

Unit: mm(inch)

| MODELS | 2660/2680/26120/26160 | 3060/3080/30120/30160 |

| Swing over bed | 660 (26) | 760 (30) |

| Swing over cross slide | 454 (18) | 556 (22) |

| Distance between centres | 1500 (60)/2000 (80)/3000 (120)/4000 (160) | |

| Spindle nose | A2-11 | |

| Spindle bore | 104 (4.125)/155(6) | |

| Tailstock spindle travel | 300 (12) | |

| Tailstock barrel diameter | 105 (4.125) | |

Standard Equipment:

- Automatic lubrication pump for slideways and ballscrews

- Automatic spindle speed gear change

- Cutting fluid coolant system

- Full enclsoed end guard

- Headstock/gearbox oil cooler design

- Full length rear splash guard

- Front moveable chip trolley

- Working light

- RS-232 port

- Leveling blocks

- Centers & center sleeve

- Service tools & toolbox

- Instruction & parts manual

Optional Accessories:

- Manual type 3-jaw/4-jaw chuck

- Hydraulic hollow chuck

- Elec. 4-way toolpost

- Front mounting elec. 8-station automatic tool changer turret

- Hydraulic tailstock

- Rotating center

- Roller type steady rest

- Roller type follow rest

- Chain type chip conveyor

- Special functions by consult